|

| Paragraph 349 of the Standard Code of the American Railway Association 1897 contains the required grade crossing whistle signal. Two long, followed by two short blasts. ___ ___ _ _ |

Friday, 27 October 2023

Whistle signals

Friday, 20 October 2023

Turntable build part 3

Next, I laid seven roundhouse tracks. I've only got six locomotives, but you never know. While I don't have the appetite or the budget at the moment for another locomotive, perhaps one day someone will release a really nice turn-of-the-century locomotive (I wouldn't mind an 1870-80s wagon top boiler ten-wheeler with a balloon stack). Truth be told there will be my two-stall enginehouse at the other end of the layout, so in fact there will be storage space for three extra locomotives, but that's academic right now. There's an overhead photo below showing the outline of where the roundhouse walls will go when I get around to building those (planning for a stone roundhouse).

I've put in an overshoot track so all tracks coming from the yard have something on the other side of the turntable. Since the photos below were taken I've trimmed the overshoot track a little. The overshoot track is also wired with power in case locomotive pickups are on the overshoot.

As the track work was coming together I made a few compromises and changes from the original plan. The photos show the coaling tower closest to the turntable with the MoW track extending behind. In theory, I could spot a coal gondola there to service the tower. However, I've since trimmed the MoW track and placed the water tower closest to the turntable. It feels a little less cluttered and while that means I can't spot a coal gondola behind the tower, I think that will be secondary overall to the general feel of the scene.

The second compromise was the caboose track. I really didn't want anything in front of the turntable to block the view. But in the end, this was the only space/most logical space I could think of for the cabeese. In reality, there should only be a few cabeese on this track at a time, which shouldn't block the view too much, and may add some foreground interest once the roundhouse is built. I've placed the track heading off the edge of the layout, hopefully giving the impression there is more to the track than is shown on the scene. In theory, it could serve as an attachment point in the future if I ever needed to attach a module there.

Coming up next I'm looking to build my own hand crank mechanism for rotating the turntable without reaching into the scene.

|

| The caboose track has a pin to prevent cars from rolling off the layout. But I liked the idea of a track disappearing 'off layout'. |

Friday, 13 October 2023

Miniatures

If you're familiar with this blog then you will have read of the miniature painting talents of my father who has painted all the figures for the railroad. I wanted to share some photos of other scale figures he painted from the American Civil War and Native American Wars.

I'm always impressed by the level of detail he is able to bring out through his painting methods. In particular, I think the eyes are able to convey so much emotion and drama.

I hope you enjoy this selection of photos of his miniatures as much as I do.

Friday, 29 September 2023

Turntable build part 2

I wasn't sure about the best way to model the edge of the turntable pit wall and had thought about printing out a stone or brick pattern and lining the edge with it. But I decided I wanted something with more texture so I tried carving stone work into DAS air dry modelling clay. The results were lacking, but perhaps with some practice, I could make it work. But I tried carving, or rather scoring, some extruded foam. I was quite happy with the look. To paint it, I started by painting individual bricks either grey, raw or burnt sienna or raw number, which looked awful at first. I then dry-brushed white over all the stones, which tied everything together a bit more. But the final black wash toned everything down and gave a cohesive look to the masonry, as well as providing shadows in the mortar lines.

To make the pit rail I began by measuring the length of rail I'd need and cut a piece of flex track half that length, then cut the ties in half, so I had two halves of the pit rail. I slowly bent these to shape by hand and used a steel weight as a jig. I kept checking the curve against a circle drawn with a compass to make sure I had the right profile. Once it was close enough, I glued the rail and ties down and ran wires to the main layout bus.

Then it was a battle of slowly aligning the approach tracks. I worked with one track at a time, leaving a little extra length, that I trimmed once the glue had set. Before I begin the scenery at large, I will paint all the rails and ties.

The turntable is reasonably short for my biggest locomotives like the 4-6-0. Overshoot tracks will be needed opposite all approach tracks and a real-life crew may have fun trying to balance the table with a larger engine. However, I was aiming to depict a turntable that was possibly struggling to keep up with the development in locomotive technology. With new locomotives getting bigger rapidly railroads were constantly having to update infrastructure to cope.

|

| The painted foam stonework glued in place. |

|

| The bridge in place. The girders are glued in place. Decking and details to come. |

|

| An overall view of the turntable and the approach tracks glued down. The two tracks at the left have screws temporarily keeping the track in place while the glue sets. |

Friday, 15 September 2023

Locomotive bell and whistle cords

|

| A 1/72 Scale Junkers JU88 I made up with my son, featuring a radio aerial wire, which gave the idea for using the same method for bell and whistle cords. |

|

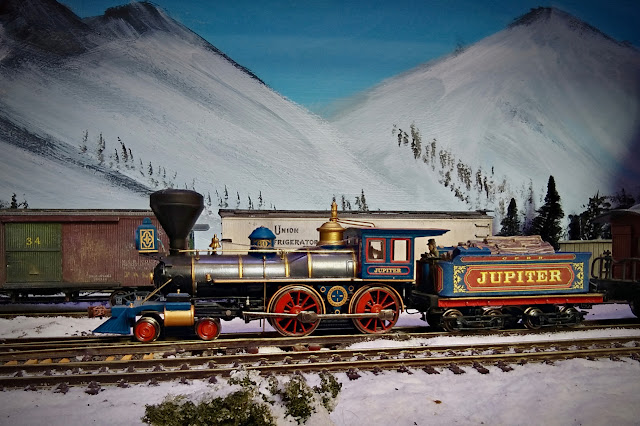

| The bell cord and whistle lever are visible in this photo of the Jupiter, taken on the old Thoroughfare Gap layout. |

Friday, 1 September 2023

Joining modules

Aligning layout modules seems to be a pretty important thing if you want trains to be derailment-free across the joins. I started by joining the modules together using 8mm bolts and T-nuts in the module faceplates. The T-nuts on one end of each module have the threads drilled out so the bolt tightens the two modules up against each other. I'd thought that this would be accurate enough, but I noticed after taking two of the modules apart that there was a tiny little bit of play. I managed to line things up manually and then tighten the bolts. But I think I will drill some holes and add some alignment dowels to help in the future. It is not like I'm pulling the layout apart a lot. It's a home layout designed to move instead of a dedicated show layout that moves all the time.

The other thing about the 8mm joining bolts is that each T-nut is part of the wiring bus, having a positive or negative bus wire soldered to it. So when the bolts are in place, they carry the power between the modules, meaning I don't have to worry about wires hanging down or making other connections.

To keep the rails aligned, I've also glued small brass plates at the end of each module and soldered the rails to them. I've seen people use PCB for this purpose, but I don't have access to a reasonably priced supply, so I used brass sheet, of course making sure I cut the plate in half after soldering and glueing to prevent short circuits. So far this is working well. All my trains are crossing all the module joins nicely and smoothly. Hopefully, once the rail and ties are painted and ballasted the plates should blend in much better than they do right now.

|

| Brass end plates where the modules meet. |

Friday, 18 August 2023

Turntable build part 1

I've been slowly chipping away at my turntable build. I had two turntables on my previous layout. One was a wooden gallows turntable, which I'm keeping for the town that will feature at the other end of the new modular railroad. However, I wasn't happy with the turntable that used to be placed at Erewhon on the old layout, mainly because it was mainly a freelance design as I hadn't seen any photos from the turn of the 19th century with anything that looked close.

Earlier this year we visited the Pleasant Point Railway, which is not far from Timaru and one of the attractions was helping turn a rail-motor car on the turntable, which had a pit, with the turntable bridge being the more conventional design with the girders underneath the track. I decided to model something similar and found some prototype pictures of turntables from the period to give me something to base it on loosely.

|

| Northern Pacific Railroad roundhouse at Lester, circa 1910 |

|

| ‘Colorado Midland Engine 20 on turntable’ |

My turntable bridge was made from a piece of 20mm plywood. I carefully measured, cut and centred a bit of straight set-track. I reused the girders from the previous turntable. I will glue them on later, presently they are just resting in place for the photo. I've had a go at carving masonry blocks into insulation foam for the turntable pit wall. I'm pleased with how it turned out. The next step will be to paint the stonework and then glue it into place. Then I can lay the pit rails to power the turntable. The last thing will be to add decking, made from strip wood and balsa to the turntable bridge.

I am considering adding a hand crank to rotate the turntable. My main concern will be to ensure it is geared low enough to be easy to turn and accurate enough to align manually. I may just settle on turning the bridge by hand. But I would like to watch the table turn around, seemingly by itself.